AlexLoop remote tuning

When I'am on vacation I use two types of antennas. A FUCHS-ATU and the AlexLoop MLA. Both have Pro and Cons. For me, the most disadvantage of the MLA design is the very narrow bandwidth. Everytime I change the frequency, I have to adjust the antenna as well. Shure, the antenna can be placed next to the operator, running QRP. When the weather is not within your comfort zone and you want to stay inside the house you need some remote hand to do the tuning.

The idea of remote-tuning the AlexLoop had been in my mind for many months.

What do you need?

- Geared motor with a very slow RPM output

- Remote controller with two or more channels

- Electronic to control the motor

- Mechanical gear to drive the rotary capacitor of the AL

After some research I found resources for every part needed.

- Geared motor: Conrad Bestell-Nr.: 1289388 Hst.-Teile-Nr.: G1000 | EAN: 4037373693313

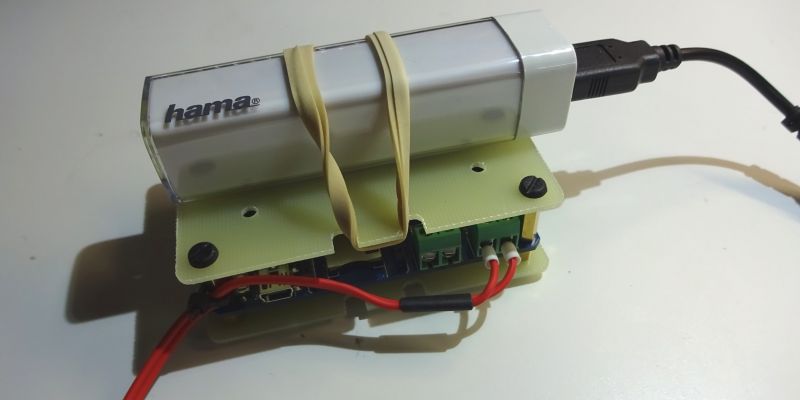

- Remote Control: https://hobby-elektronik.ch/Module-Sensoren/Funk-Netzwerk-RFID/433-Mhz-Fernbedienung-4-Kanal-Lernfaehig-mit-Empfaenger::705.html

- Motor control: https://www.itead.cc/mboard.html(I ordered this hardware many months before this project)

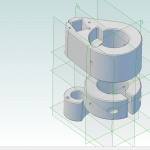

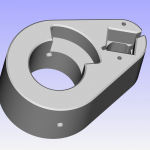

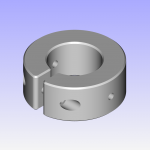

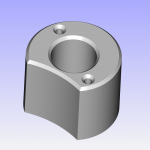

- Construction parts: Built with Ultimaker 3D Printer and Alibre 3D CAD software.

How it works:

The main problem was how to connect the motor to the tuning capacitor of the AL. Removing the knob and make a direct connection to the motor is easy but not easy to sense limits. The gear has a 1000:1 transmission and a lot of power. It would need a friction clutch to avoid mechanical damage of the variable capacitor.

Solution:

I use a small round abrasive belt (Dremel or Proxxon) as driving element. It is pressed to the AL knob using rubber rings attached to the fixed base ring. If a mechanical end of the capacitor is reached, it just scratches over the blocked knob. No damage occurs

Controlling hardware

I used a MBOARD to control the brushed motor. The remote control hardware has four digital outputs which corresponds to the four buttons on the remote transmitter. If you press a button, the receiver set the related output. It also sets the 'received valid data' signal which is checked by software. Two buttons move the motor at full speed for both directions. The other two just send a first pulse to the motor and if the button is pressed longer the motor turns with a lower speed continiously.

You can use any other motor control hardware. The main goal is to use a motor with a very high reduction gear and a controller to drive the motor at two different speeds.